Bird Bros, a family-run egg production company, is enhancing operational efficiency with the installation of high-tech equipment, including robots and solar-powered systems, as part of its commitment to sustainability.

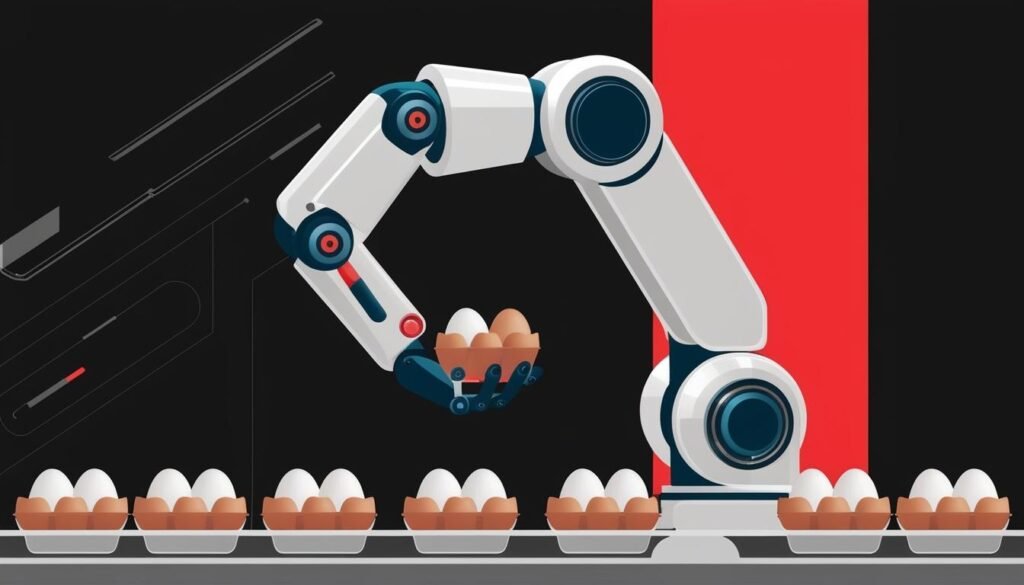

Bird Bros, an established family-run egg production company, is making significant strides towards automation and sustainability with a series of high-tech equipment installations aimed at enhancing operational efficiency. Located in Swineshead, the company is implementing new machinery for washing, packing, and stacking pallets, a move aimed at streamlining its production processes.

Recently, Bird Bros installed a Unifortes pallet washer, which is anticipated to dramatically enhance cleaning efficiency. Plans are already in motion for the introduction of a state-of-the-art case packer robot scheduled for January. Following this, the company will add an Endoline Robotics palletiser by February 2024. The introduction of these advanced technologies signals a continued commitment to productivity improvements, particularly in precision and overall efficiency in manufacturing practices.

Matt Bird, the commercial director at Bird Bros, shared insights into the company’s evolution, stating, “Our family business began with one hen house on farmland in Swineshead – fast forward 50 years and here we are installing cutting-edge robotics as we supply up to five million eggs a week across the UK.” This transformation reflects a broader trend in the industry towards embracing automation and robotics as essential tools for scaling production.

A noteworthy aspect of this investment is the incorporation of sustainability measures. The new equipment will be predominantly powered by solar energy, with over 800kw generated through solar units. This effort not only aims to reduce electricity consumption but also aligns with broader environmental objectives by limiting wastewater production, as Matt Bird elaborated further, stating, “This million-pound tech investment will be a game changer when it comes to improving efficiency. As well as reducing wastewater, the pallet washer means we’ll no longer be jet-washing by hand, and the robots will help to create a safer working environment by reducing heavy lifting and repetitive work while allowing us to upskill our people in other areas.”

The automation initiative is part of Bird Bros’ larger ‘Vision 2028’ strategy, which entails a significant shift in production practices. The strategy includes phasing out colony cage egg production over the next four years, with a goal of complete cessation by 2028. This is also an extension of their goal to fully automate their production line, which has been nurtured for the past four years. Notable previous investments include the installation of four new case erectors from Endoline Automation in 2021, which resulted in a 10% boost in production efficiency. The innovative design of the slimmer 251 case erectors, measuring just 1 metre by 2 metres, was particularly beneficial given the space constraints within the factory.

While Bird Bros is making significant advancements in automation, Unilever has also embarked on a transformative journey within its largest UK food factory in Burton. The company has invested £40 million over a five-year span, streamlining its UK condiments production under one roof, showcasing another instance of industry-wide tendencies towards automation and operational optimisation.

As both companies navigate the shifting landscape of food production and processing, their investments in emerging technologies and sustainability practices reflect a common future trend in the business sector that prioritises efficiency, safety, and environmental responsibility.

Source: Noah Wire Services

- https://www.farminguk.com/news/uk-egg-producer-invests-1m-in-game-changing-automation_65774.html – Corroborates the investment in automation, the installation of a Unifortes pallet washer, and the introduction of a MOBA MR12 twin case packer robot and an Endoline Robotics palletiser.

- https://www.farminguk.com/news/uk-egg-producer-invests-1m-in-game-changing-automation_65774.html – Provides details on the sustainability measures, including the use of solar energy and reduction of wastewater.

- https://www.farminguk.com/news/uk-egg-producer-invests-1m-in-game-changing-automation_65774.html – Explains the company’s ‘Vision 2028’ strategy and the phase-out of colony cage egg production.

- https://static1.squarespace.com/static/620365047e92571e5f736d66/t/643602ce6103ca2e98515b38/1681261278127/unifortes_General_spreadsLQ.pdf – Details the features and benefits of the Unifortes pallet washer, including its efficiency and hygiene standards.

- https://www.foodmanufacture.co.uk/Article/2021/03/11/Egg-packer-Bird-Bros-fully-automates-production-line – Corroborates the previous automation efforts, including the installation of Endoline 251 case erectors and MOBA MR-12 dual robot loading cells.

- https://www.foodmanufacture.co.uk/Article/2021/03/11/Egg-packer-Bird-Bros-fully-automates-production-line – Provides insights into the benefits of automation, such as increased efficiency and reduced food waste.

- https://unifortes.com/systems/pallet-washer/ – Describes the advanced technology and cost-effective solutions of Unifortes pallet washers.

- https://www.farminguk.com/news/uk-egg-producer-invests-1m-in-game-changing-automation_65774.html – Quotes Matt Bird on the company’s evolution and the impact of automation on their operations.

- https://www.farminguk.com/news/uk-egg-producer-invests-1m-in-game-changing-automation_65774.html – Highlights the safety benefits of the new equipment, including reducing heavy lifting and repetitive work.

- https://www.foodmanufacture.co.uk/Article/2021/03/11/Egg-packer-Bird-Bros-fully-automates-production-line – Mentions the redeployment of staff from monotonous roles to other areas due to automation.

- https://www.farminguk.com/news/uk-egg-producer-invests-1m-in-game-changing-automation_65774.html – Details the company’s current production capacity, supplying up to five million eggs a week across the UK.